I’m pretty sure I wouldn’t have believed it if 5 years ago you’d told me I’d start a business to build a machine to sort fruit flies. I’ve worked for more than 10 years in product design. I’ve come up with maybe a hundred different ideas for new products, and have been approached by countless people who have their own ideas for new products. And yet, out of all of those ideas, the only one that stuck and lead me to start a company is sorting fruit flies?

[ This is the second post about what’s happened since I started FlySorter last year. You can find the first here. ]

One of the hardest parts of product design is handling ambiguity. At the beginning of almost every project, there are tons of open questions, and if you had to chase down the answer to each one before you could build something, nothing would ever get built. So instead, you make some assumptions (or guesses), and move on. It’s critical, however, to come back and reevaluate those assumptions periodically, and fill in more details as the situation allows.

For me, building a fly sorter seemed to be a wonderful combination of a challenging and interesting engineering task, something that was arguably good for the world, and a good business opportunity. As I built the prototype, the first two of those were reinforced, but the third remained somewhat unknown. Even if it was a good problem to solve, was it really a good business idea? After all, FlySorter has taken no capital investment, and I’m not drawing a salary while I develop the first product(s). So by March, the time had come to revisit the assumption.

To address the question, I took the show on the road, and attended the 55th Annual Drosophila Research Conference in San Diego at the beginning of April. Though I didn’t rent a booth (the cost was prohibitive), I did bring photos and video of the prototype, and talked with pretty much anyone who would listen. I learned a bunch more about fly science (remember, I’m an engineer, not a biologist), and how much time different researchers spent sorting.

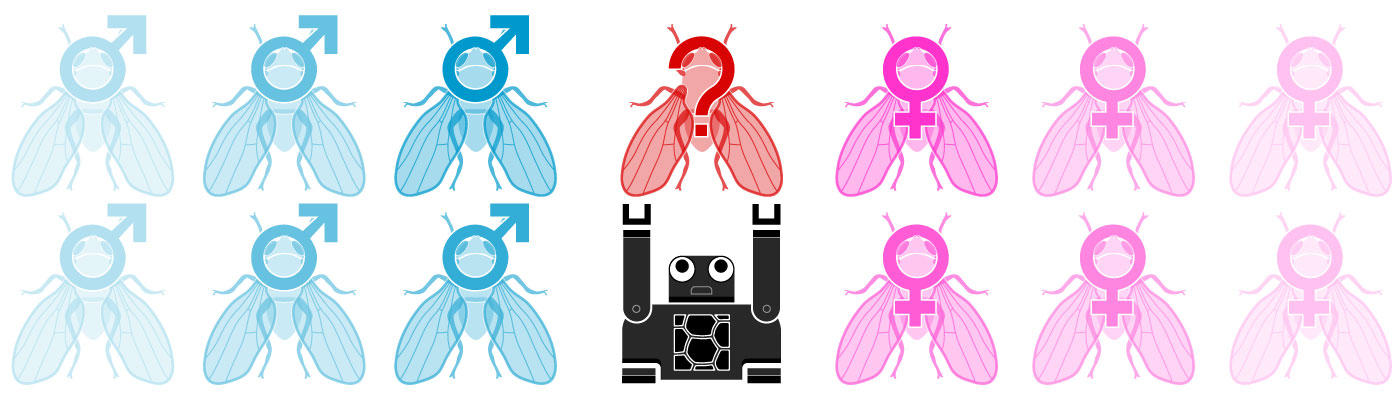

Of course I was hoping that I’d come home having sold lots of sorters and built a mailing list of hundreds of people, but that wasn’t very realistic (especially since I didn’t really have a product yet). Instead, I came back with a much clearer idea of the range of solutions that people needed — specifically, the breakdown of how many flies per week different labs handled/sorted, and what criteria they sorted on. My prototype sorts based on sex, but there are of course many ways that people sort, including by eye color, virgin status, fluorescent proteins, to name just a few. I got a better understanding of how sorting fits in to the workflow in a lab, and what features would make a sorter worth buying to a variety of researchers.

And, happily, I did sell a couple of machines at the conference. I’m partnering with a lab that sorts upwards of 30,000 flies a week at times, and looking forward to putting the system through its paces.

For certain, there are still open questions about the market for the fly sorter, but for now I feel confident that it’s worth more of my time, energy and money to further develop the technology.

Next up: a new prototype, and spreading the word.