Since the conference at the beginning of April, I’ve spent most of my time working on the software — mostly focused on making it more robust and user-friendly. The first couple weeks of June, however, were almost entirely spent building up fly sorter serial #1. Though the design wasn’t 100% complete, I’d been talking with a lab that was eager to get its hands on a sorter, so much so that they’re willing to help with testing and validation, and I agreed to build them one. I’m thrilled to have such a great first customer!

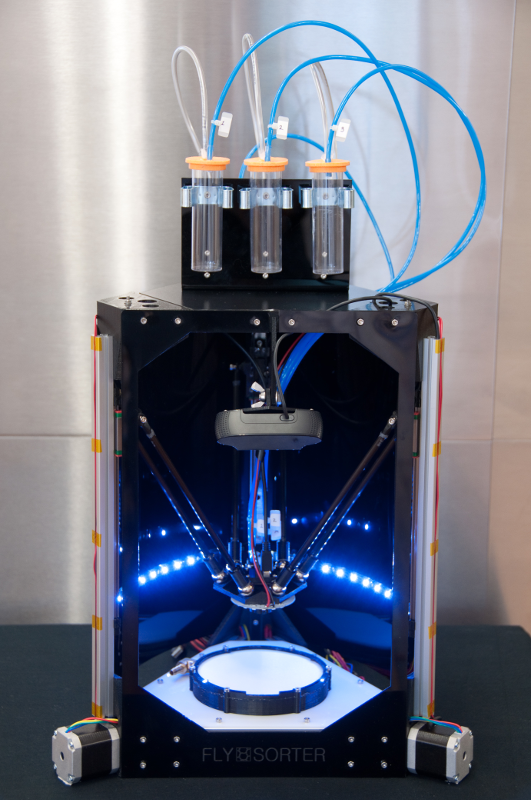

That’s what it looks like before it goes together. These parts, plus a bunch of fasteners, wires, and electronics are carefully assembled and tested, and it comes out looking like this:

The robotic system is based off a very successful open source 3D printer called the Kossel, which is also a delta robot. I’ve redesigned most of the parts and swapped out the end-effector from a plastic extruder to a custom platform that includes illumination, digital imaging, and vacuum nozzles for manipulating flies. And of course the biggest difference is in the software, which recognizes flies, classifies them by sex, and directs the robot to sort them into vials.

Now that the first sorter is in a lab, I’m getting emails on a regular basis with bug reports, enhancement requests, and general feedback about using the machine. It’s immensely helpful, and keeps me quite busy. Just the same, I’m working to develop new features (like sorting by eye color, or presence of fluorescent proteins), and am also scouting around for more labs to help with testing. Interested? Send me a note!